Roy's 5Axis CNC - Collab Style Rapid Design

Hello internet family. I am creating this campaign in the hopes of helping others, while also trying to get my own ideas off the ground and created in reality. In our world 3d printing has enabled many people to make their ideas come to life very inexpensively. This kind of manufacturing has endless applications, however, there are some applications where a different solution is needed.

CNC machines enable parts and designs to be made in metal much quicker than 3d printing, and at a much lower material cost as the materials have been readily available for forever. The problem is that getting access to quality CNC machines, and the software to run them, can be quite expensive. Finding someone with the design and software skills to take your idea and make it real, is also difficult. I have an idea to help out with that.

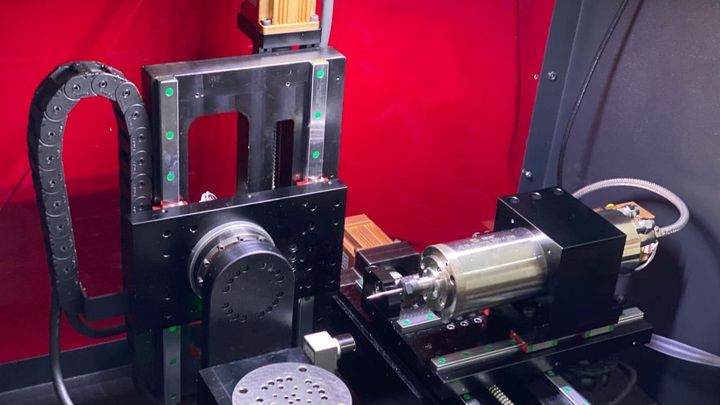

I am wanting to purchase, with the help of my internet family, a Desktop NC (small form factor 5-axis CNC – from xinshan ), so that I can put my skills to work. This is a servo-based “desktop” milling center, that has been proven to work to cut materials up to a hardness of G5 titanium although optimally cuts delrin, aluminum or softer steels. Yes, it's smaller - but the chances to grow are always bigger with a stepping stone.

I am extremely fluent in design language and creating parts and plans in 3d modeling software. As well as being educated as a mechanical engineer. Being able to have this machine will enable me to make designs a reality. The bigger benefit, especially for those that choose to support my vision, is that I will be able to offer my services to those that need them for little to no cost (outside of the materials needed).

I am proposing to continue offering my services to those that need/want to have parts/models designed to their specifications and then machined from the material of their choice. Instead of paying a ton of money for consulting and design, I would charge minimal R&D fees and then would only charge the cost of the materials used in producing said parts/models/designs, plus a small fee to cover the expenses to run the machine (electricity y’all). I’m not looking to create a profit model, I’m looking to create a model, where I’m here to help others do their thing - but with expanded capabilities

And If my services are not what you’d like, I have a small team of TRAINED Solidworks CAD designers – or you could just send a model; the difference here is I can add small subtractive manufacturing to my ability of additive manufacturing.

If you would like to support this cause, and benefit from it as well, please feel free to donate. as much as I say that I would love to just have it for myself, I would never be the one to not offer anything I have to help anyone else in their pursuits

If you have any questions please ask and I will happily answer them to the best of my ability. I set the donation amount to a point where “everything” would be included – where the only thing needed after setup is shakedown cuts.

And for the ones who don't know who I am and what I stand for - I am a US military vet technophile - I never stop trying to improve anything I can, and I have been known to help others with my skills before I help myself. I have been an ASE certified mechanic, Certified CAD engineer, among many many other skill sets - I take the time to learn everything i can about each and every subject, and have been doing that for both my hobby and professional careers. I am not interested in profit from my exploits, I am just looking to help others achive their dreams.