Student project needs help to finance the launch campaign

Donation protected

We are Team PERSIS. PERSIS is an acronym for Photopolymer Extrusion of Reinforced Structures In Space. We are developing a system to extrude carbon Reinforced Photopolymer profiles in space. In the future this method might help to build structures in space that are to large to launch and safe a lot of weight as the structures don't need to survive the launch loads. This will reduce costs for large structures enable previously impossible structures and safe materials.

With our concept we convinced the German Aerospace Association (DLR) to let us take part in the prestigious student project REXUS. REXUS is a German Swedish framework for student experiments on Sub-otbital rocket flights.

After two years of hard work we are finally launching at the RX33 campaign in March.

The Launch will take place at ESRANGE in the far north of Sweden. We are very excited for the campaign wich will consist of two weeks of hard work to finally integrate our project into the Rocket. We are a team consisting of ten students yet only for four of us there is a sponsorship for the travel expanses for the two campaign weeks. For the finalization of the integration process we will need at least eight people for the two weeks with our additional members joining for the second week. The travel expanses for the remaining students will be around 1500€ for the members joining for two weeks and around 900€ for everyone joining for the second week. In total the cost will be around 8000€ which is a substantial amount for us as a student project.

We are kindly asking for you to help us finance this important trip. As a group of students and recent graduates this sum puts a severe strain on us. We are determined to make this project a success after these two years of hard voluntary work. We are grateful to get this unique opportunity and we thank everyone who supported us along the way and we will be greatful to everyone who helps us finish this great project.

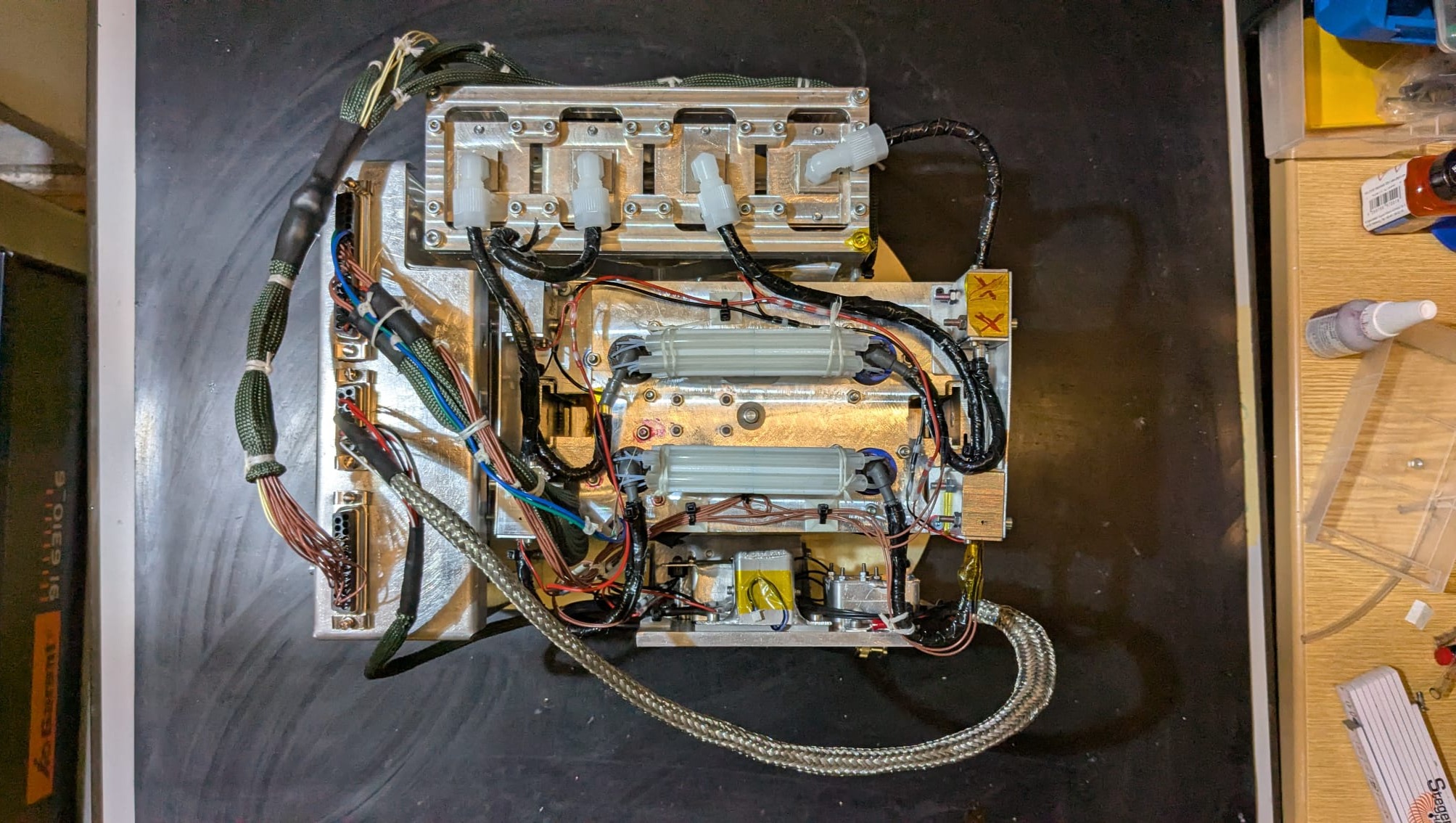

Top view of our experiment with all pipes and the carbon fibre routing system.

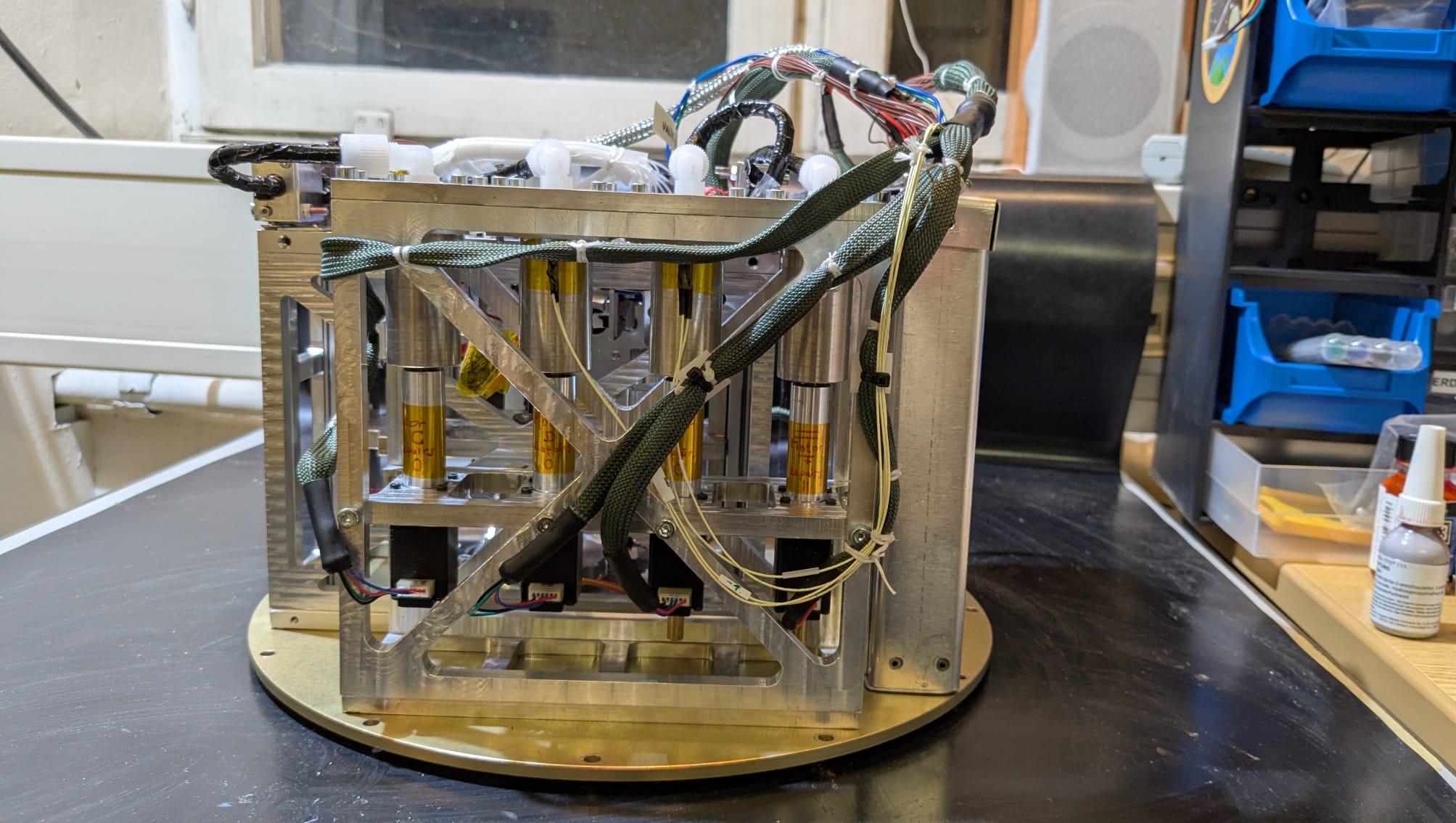

Back view: with the resin storage and the extrusion linear motors.

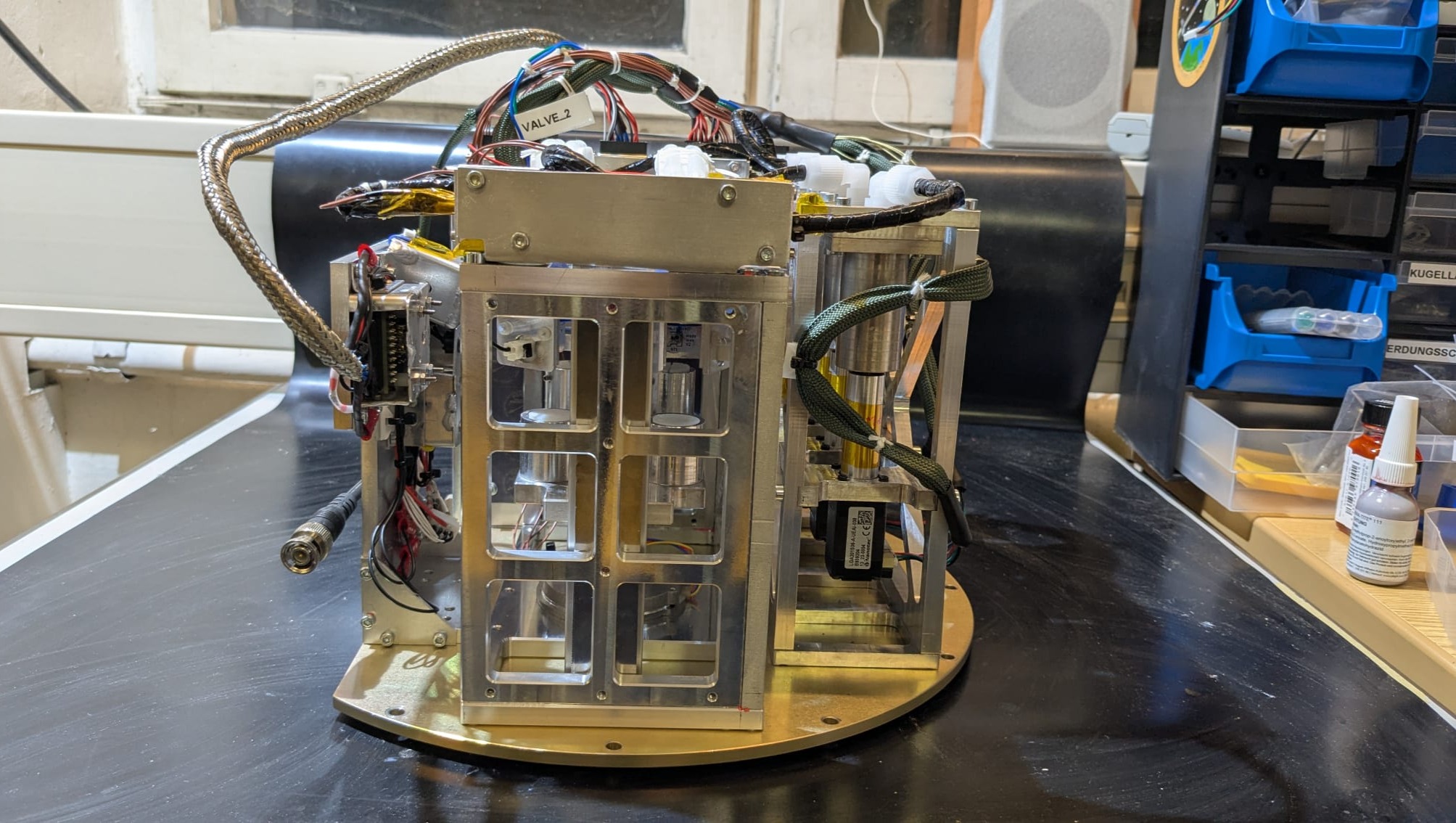

Side view: with the printing bed and UV-LED module for the photopolymer curing. On the left there is the camera subsystem with an infrared camera for temperature measurements. A analogue camera for a live transmission during the flight and a digital camera for high quality recording.

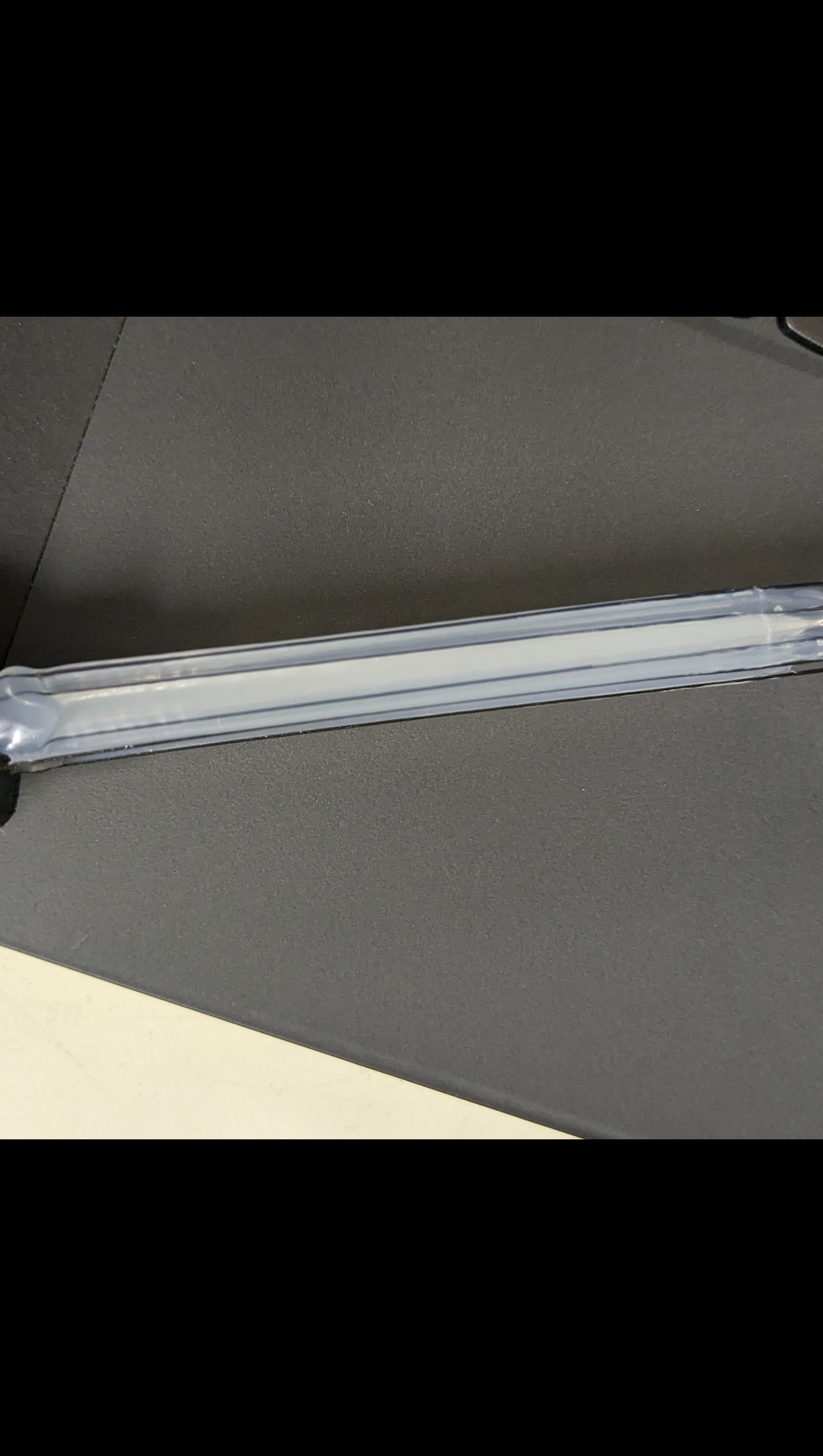

Extruded I-Beam Reinforced with carbon fibres.

Organizer

Eric Hennig

Organizer

Munich, Bayern