20,000 Face Shields Project

Donation protected

Join Us to make 20,000 reusable face shields to keep our healthcare workers safe from COVID-19! Not everyone has the tools like 3D printers so we’ve purchased an injection mold to produce large quantities of face shields (up to 1,000 face shields per day) and at less than $2.25 per face shield.

6,625 Face Shields delivered so far! (Updated 10/25)

• Garden Grove Hospital

• Prudential St. Joseph Hospital

• Keck Medicine of USC Hospitals

• Kaiser Permanente Baldwin Park

• Kaiser Permanente Downey

• St. Francis Lynwood Hospital

• Lakewood Community Hospital

• Fountain Valley Hospital

• Parkview Riverside Hospital

• Northridge Hospital Medical Center, Dignity Health

• St. Mary Medical Center Long Beach, Dignity Health

• Long Beach Memorial Care

• Glendale Memorial Hospital, Dignity Health

• Los Angeles County Hospital

• Huntington Hospital

• Healthcare Partners Pasadena

• Healthcare Partners Arcadia

• Paradise Valley Medical Center

• San Gabriel Valley Medical Center

We need your help! Your donations will go directly to face shield production.

We’ve taken the 3DVerkstan face shields design by Erik Cederberg and partnered with manufacturing company, Proto Labs to produce the the visor components at large volumes. Proto Labs based in Minnesota specializing in injection molding has been gracious in waiving the expedite costs for the injection mold of the visors and produced the first samples parts in under 4 days! Avery Products has been super supportive in this effort; from designing and purchasing of the cutting dies, producing and graciously donating 5,000 clear sheets.

We’ve taken the 3DVerkstan face shields design by Erik Cederberg and partnered with manufacturing company, Proto Labs to produce the the visor components at large volumes. Proto Labs based in Minnesota specializing in injection molding has been gracious in waiving the expedite costs for the injection mold of the visors and produced the first samples parts in under 4 days! Avery Products has been super supportive in this effort; from designing and purchasing of the cutting dies, producing and graciously donating 5,000 clear sheets.

Just an amazing experience working with the teams at Proto Labs and Avery Products. They truly have stepped up to support the maker community effort.

How Did We Start?

We’re Chia and Jeannes from Los Angeles. We hear heartbreaking news every day of the huge Personal Protective Equipment (PPE) shortage. As a result, our healthcare professionals are not able to protect themselves while taking care of patients with COVID-19. In some cases, because of the shortage, these healthcare professionals have now become patients themselves.

We’re Chia and Jeannes from Los Angeles. We hear heartbreaking news every day of the huge Personal Protective Equipment (PPE) shortage. As a result, our healthcare professionals are not able to protect themselves while taking care of patients with COVID-19. In some cases, because of the shortage, these healthcare professionals have now become patients themselves.

Chia was inspired by the many grass root communities jumping to action. Being engineers and makers, we knew we could rise to the challenge and help. We researched many DIY reusable face shields and found Erik Cederberg’s 3DVerkstan awesome visors. With simply two parts (Visors and Clear Rigid Sheet), it can be assembled to make face shield without needing any elastic bands. With this design we began 3D printing the visors and purchased several clear sheets to prototype.

Chia was inspired by the many grass root communities jumping to action. Being engineers and makers, we knew we could rise to the challenge and help. We researched many DIY reusable face shields and found Erik Cederberg’s 3DVerkstan awesome visors. With simply two parts (Visors and Clear Rigid Sheet), it can be assembled to make face shield without needing any elastic bands. With this design we began 3D printing the visors and purchased several clear sheets to prototype.

With several samples in hand, we visited the Keck Hospital of University of Southern California (USC) in Los Angeles to get feedback. They were thrilled to see the prototypes and offered suggestions to improve the design for better comfort and protection which we’ve incorporated. USC Keck Hospital wanted as many as we can produce. We also visited other hospitals and we quickly realized we need to be making thousands of these face shields.

*Nerd Alert*

Our 3D Printer is good, but it takes a very long time to just get to 1,000. We calculated how long this would take:

40 minutes to print one visor

40,000 minutes for 1,000 visors

40,000 minutes = 667 hours = 67 days

*Assumption: 3D printer works 10 hours a day

We bought another 3D printer to cut the time down, but there was no way we could quickly get to the number of face shields needed.

We decided we need to approach this in 2 different paths:

- Produce as much as we can using our 3D printers, printing 2 visors every 40 minutes

- Begin looking into injection molding that can produce up to 1,000 visors daily.

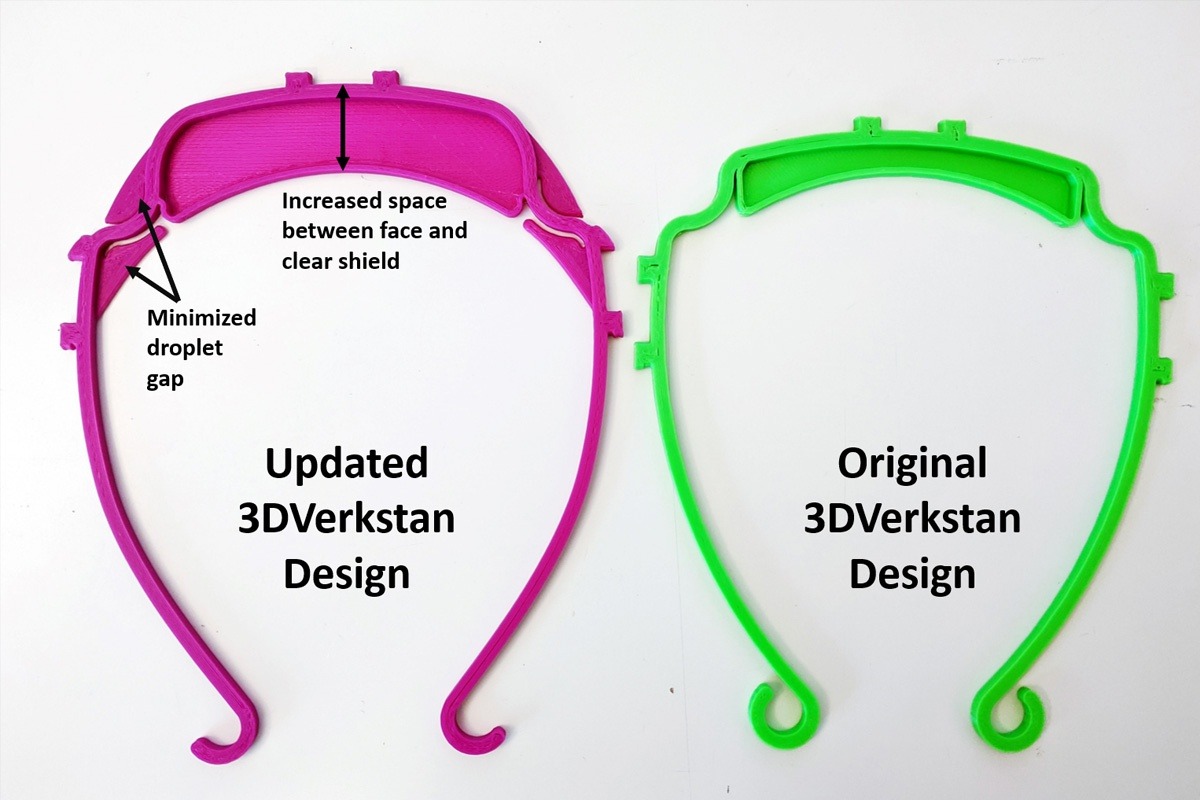

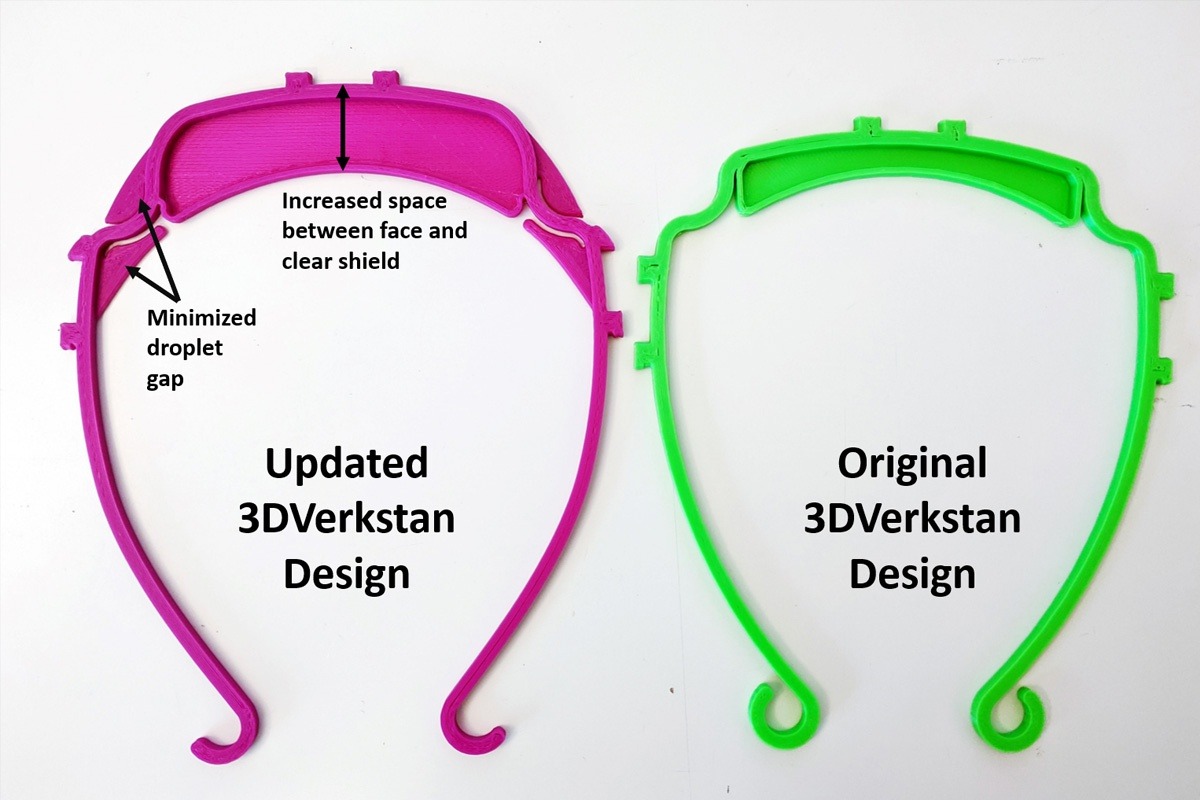

Chia took feedback from the hospitals and made improvements to the 3DVerkstan design. More space between the clear shield and face was added and reduced gaps in the visor to minimize droplets from entering above the face shield. After this, the design was optimized to make it possible to be injection molded. At this point Chia began working with Proto Labs to quote and build the injection mold tooling for molded parts. The team at Proto Labs was so quick to respond. They made every effort to provide feedback on the design and got their engineers and staff involved to expedite the mold and produce first parts in under 4 days!

Chia took feedback from the hospitals and made improvements to the 3DVerkstan design. More space between the clear shield and face was added and reduced gaps in the visor to minimize droplets from entering above the face shield. After this, the design was optimized to make it possible to be injection molded. At this point Chia began working with Proto Labs to quote and build the injection mold tooling for molded parts. The team at Proto Labs was so quick to respond. They made every effort to provide feedback on the design and got their engineers and staff involved to expedite the mold and produce first parts in under 4 days!

With the visors taken care of, our next step was to figure out where to purchase the clear sheets. With online stores running out of these, Jeannes reached out to her co-workers at Avery Products to see if they carry this type of materials and if we could purchase 5,000 sheets from them. Their reaction blew us away! They decided to give these sheets away and started the chain reaction to get other people to help in this effort. These sheets are not even product that Avery typically carries. Therefore new cutting dies had to be designed & purchased. The sheets also require special manufacturing run to get it to the format we need. This took people’s time and effort, and yet all we heard was they were eager and proud to contribute. We are so thankful!!

Our first injected molded parts with fun colors from Proto Labs and clear rigid film from Avery.

What's Next?

The tools to make face shields are ready! Join us and contribute to making parts. Your donations will go directly into producing face shields.

Below are the quantities of face shields that can be donated with your contributions

- $20 - 8 face shields

- $50 - 22 face shields

- $100 - 44 face shields

- $250 - 111 face shields

People who have helped us along the way:

Protomold:

Doug, Anthony and team

Avery Products:

Manuel , Xavier, Mariano, Roberto, Eliud, Dawn, Alex, Gerardo, Andy, Le, Jay

USC:

Kymberly

Darryl

Face Shield Design:

Erik Cederberg (3DVerkstan)

apip (Thingiverse)

joshtreekpark (Thingiverse)

Frequently Asked Questions (FAQs):

Are these face shields currently used in other hospital?

The original 3DVerkstan model has been approved by Columbia University Medical Center/New York-Presbyterian Hospital staff, who are currently using hundreds of them.

See NIH reference https://3dprint.nih.gov/discover/3dpx-013306

Does GoFund Me Charges Transaction Fees?

They do. Transaction fee is 2.9% plus $0.30 per donation

How will the funds be used?

100% of your contribution will go directly into producing face shields.

Are donations tax deductible?

Currently, donations are NOT tax-deductible.

How are the face shields being produced?

The visor will be injection molded and the tooling can produce a maximum of 20,000 parts.

What happened to the remaining funds if this campaign were to be successful and exceed the goal?

Depending on how much extra money is leftover beyond producing the 20,000 face shields, the money will either used to buy more visors or another mold with one cavity or two cavities ($6,000 - $9,000) and cutting dies (~$1,500) so even more visors can be produced. Your money will not go to waste. We will donate any unused funds to the hospitals.

What can I do to offer additional support?

Please SHARE our GoFundMe Campaign and help spread the word on your social media.

Let’s build 20,000 face shields together and support our healthcare professionals!

6,625 Face Shields delivered so far! (Updated 10/25)

• Garden Grove Hospital

• Prudential St. Joseph Hospital

• Keck Medicine of USC Hospitals

• Kaiser Permanente Baldwin Park

• Kaiser Permanente Downey

• St. Francis Lynwood Hospital

• Lakewood Community Hospital

• Fountain Valley Hospital

• Parkview Riverside Hospital

• Northridge Hospital Medical Center, Dignity Health

• St. Mary Medical Center Long Beach, Dignity Health

• Long Beach Memorial Care

• Glendale Memorial Hospital, Dignity Health

• Los Angeles County Hospital

• Huntington Hospital

• Healthcare Partners Pasadena

• Healthcare Partners Arcadia

• Paradise Valley Medical Center

• San Gabriel Valley Medical Center

We need your help! Your donations will go directly to face shield production.

We’ve taken the 3DVerkstan face shields design by Erik Cederberg and partnered with manufacturing company, Proto Labs to produce the the visor components at large volumes. Proto Labs based in Minnesota specializing in injection molding has been gracious in waiving the expedite costs for the injection mold of the visors and produced the first samples parts in under 4 days! Avery Products has been super supportive in this effort; from designing and purchasing of the cutting dies, producing and graciously donating 5,000 clear sheets.

We’ve taken the 3DVerkstan face shields design by Erik Cederberg and partnered with manufacturing company, Proto Labs to produce the the visor components at large volumes. Proto Labs based in Minnesota specializing in injection molding has been gracious in waiving the expedite costs for the injection mold of the visors and produced the first samples parts in under 4 days! Avery Products has been super supportive in this effort; from designing and purchasing of the cutting dies, producing and graciously donating 5,000 clear sheets.Just an amazing experience working with the teams at Proto Labs and Avery Products. They truly have stepped up to support the maker community effort.

How Did We Start?

We’re Chia and Jeannes from Los Angeles. We hear heartbreaking news every day of the huge Personal Protective Equipment (PPE) shortage. As a result, our healthcare professionals are not able to protect themselves while taking care of patients with COVID-19. In some cases, because of the shortage, these healthcare professionals have now become patients themselves.

We’re Chia and Jeannes from Los Angeles. We hear heartbreaking news every day of the huge Personal Protective Equipment (PPE) shortage. As a result, our healthcare professionals are not able to protect themselves while taking care of patients with COVID-19. In some cases, because of the shortage, these healthcare professionals have now become patients themselves. Chia was inspired by the many grass root communities jumping to action. Being engineers and makers, we knew we could rise to the challenge and help. We researched many DIY reusable face shields and found Erik Cederberg’s 3DVerkstan awesome visors. With simply two parts (Visors and Clear Rigid Sheet), it can be assembled to make face shield without needing any elastic bands. With this design we began 3D printing the visors and purchased several clear sheets to prototype.

Chia was inspired by the many grass root communities jumping to action. Being engineers and makers, we knew we could rise to the challenge and help. We researched many DIY reusable face shields and found Erik Cederberg’s 3DVerkstan awesome visors. With simply two parts (Visors and Clear Rigid Sheet), it can be assembled to make face shield without needing any elastic bands. With this design we began 3D printing the visors and purchased several clear sheets to prototype. With several samples in hand, we visited the Keck Hospital of University of Southern California (USC) in Los Angeles to get feedback. They were thrilled to see the prototypes and offered suggestions to improve the design for better comfort and protection which we’ve incorporated. USC Keck Hospital wanted as many as we can produce. We also visited other hospitals and we quickly realized we need to be making thousands of these face shields.

*Nerd Alert*

Our 3D Printer is good, but it takes a very long time to just get to 1,000. We calculated how long this would take:

40 minutes to print one visor

40,000 minutes for 1,000 visors

40,000 minutes = 667 hours = 67 days

*Assumption: 3D printer works 10 hours a day

We bought another 3D printer to cut the time down, but there was no way we could quickly get to the number of face shields needed.

We decided we need to approach this in 2 different paths:

- Produce as much as we can using our 3D printers, printing 2 visors every 40 minutes

- Begin looking into injection molding that can produce up to 1,000 visors daily.

Chia took feedback from the hospitals and made improvements to the 3DVerkstan design. More space between the clear shield and face was added and reduced gaps in the visor to minimize droplets from entering above the face shield. After this, the design was optimized to make it possible to be injection molded. At this point Chia began working with Proto Labs to quote and build the injection mold tooling for molded parts. The team at Proto Labs was so quick to respond. They made every effort to provide feedback on the design and got their engineers and staff involved to expedite the mold and produce first parts in under 4 days!

Chia took feedback from the hospitals and made improvements to the 3DVerkstan design. More space between the clear shield and face was added and reduced gaps in the visor to minimize droplets from entering above the face shield. After this, the design was optimized to make it possible to be injection molded. At this point Chia began working with Proto Labs to quote and build the injection mold tooling for molded parts. The team at Proto Labs was so quick to respond. They made every effort to provide feedback on the design and got their engineers and staff involved to expedite the mold and produce first parts in under 4 days!With the visors taken care of, our next step was to figure out where to purchase the clear sheets. With online stores running out of these, Jeannes reached out to her co-workers at Avery Products to see if they carry this type of materials and if we could purchase 5,000 sheets from them. Their reaction blew us away! They decided to give these sheets away and started the chain reaction to get other people to help in this effort. These sheets are not even product that Avery typically carries. Therefore new cutting dies had to be designed & purchased. The sheets also require special manufacturing run to get it to the format we need. This took people’s time and effort, and yet all we heard was they were eager and proud to contribute. We are so thankful!!

Our first injected molded parts with fun colors from Proto Labs and clear rigid film from Avery.

What's Next?

The tools to make face shields are ready! Join us and contribute to making parts. Your donations will go directly into producing face shields.

Below are the quantities of face shields that can be donated with your contributions

- $20 - 8 face shields

- $50 - 22 face shields

- $100 - 44 face shields

- $250 - 111 face shields

People who have helped us along the way:

Protomold:

Doug, Anthony and team

Avery Products:

Manuel , Xavier, Mariano, Roberto, Eliud, Dawn, Alex, Gerardo, Andy, Le, Jay

USC:

Kymberly

Darryl

Face Shield Design:

Erik Cederberg (3DVerkstan)

apip (Thingiverse)

joshtreekpark (Thingiverse)

Frequently Asked Questions (FAQs):

Are these face shields currently used in other hospital?

The original 3DVerkstan model has been approved by Columbia University Medical Center/New York-Presbyterian Hospital staff, who are currently using hundreds of them.

See NIH reference https://3dprint.nih.gov/discover/3dpx-013306

Does GoFund Me Charges Transaction Fees?

They do. Transaction fee is 2.9% plus $0.30 per donation

How will the funds be used?

100% of your contribution will go directly into producing face shields.

Are donations tax deductible?

Currently, donations are NOT tax-deductible.

How are the face shields being produced?

The visor will be injection molded and the tooling can produce a maximum of 20,000 parts.

What happened to the remaining funds if this campaign were to be successful and exceed the goal?

Depending on how much extra money is leftover beyond producing the 20,000 face shields, the money will either used to buy more visors or another mold with one cavity or two cavities ($6,000 - $9,000) and cutting dies (~$1,500) so even more visors can be produced. Your money will not go to waste. We will donate any unused funds to the hospitals.

What can I do to offer additional support?

Please SHARE our GoFundMe Campaign and help spread the word on your social media.

Let’s build 20,000 face shields together and support our healthcare professionals!

Organiser and beneficiary

Organiser and beneficiary

Jeannes Tirtadidjaja

Organiser

Pasadena, CA

Chia Chiu

Beneficiary