TiEnd - A Next-Generation Hot-End

Donation protected

3D Printing is the new frontier of the manufacturing world, and the hottest new hobby. Home builders and tinkerers have pushed 3D printing technology forward at breakneck speeds, and now it's possible to build a printer as good as an industrial model for a tiny fraction of the cost. Every aspect of 3D printer design is being worked on; constantly evolving and improving. But some areas don't get the attention they should. The hot-end is one of those areas. Due to the tools and precision required to make quality hot-ends, it isn't accessible to the average builder. My goal is to help fill that design gap.

About The TiEnd - Briefly*

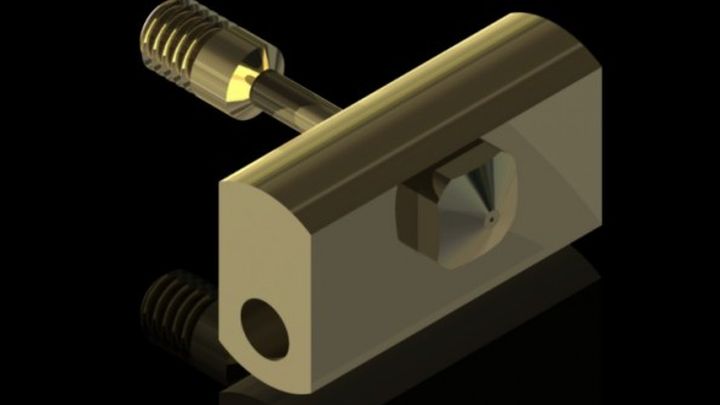

The TiEnd is the culmination of months of thought, sketches, and a small amount of mathematics. It's the next step from my previous hot-end design, which has been running successfully in the field for months without a break. I took all the design elements I liked in existing hot-ends, and rolled them together into one design along with some twists of my own. It's made entirely of titanium (both pure and Ti6Al4V alloy) for strength and ultimate thermal stability. Titanium also has a mystical awesomeness about it. It's small and light to reduce extrusion head size and weight, which can help to speed up prints. And because it's made entirely of metal and heated by a powerful cartridge heater, it can get hot enough to melt all the hot new plastics - including polycarbonate - without melting or any other adverse effects.

About This Campaign

I have already completed the designs for the TiEnd. My goal is to raise funds for materials and specialized tooling to make a batch of four TiEnds. Although I am confident in my design, I know that I can't take it out of the prototype stage until it is proven. And that's where you come in. When you donate to this campaign, you don't just get a TiEnd of your very own (and the satisfaction of making it a reality). You are helping me make the TiEnd better by using it and pushing its limits. You can tell me what works and what doesn't, and I can make it better for future versions.

About Me

My name is Jeremy Bloyd-Peshkin. I've spent the last four years building and working on 3D printers. This is my second hot-end design, and my first attempt at crowdfunding a project. I have extensive experience in machining and fabrication, and the skill to bend bar stock to my will.

If funded, I will produce four TiEnds for donors. Any remaining funds will go towards future design revisions.

*The Nitty-Gritty

The TiEnd has some unusual features. It is the first hot-end to have no aluminum or brass in it. The thermal barrier is made of alloy Ti6Al4V titanium. This alloy has a ridiculously low thermal conductivity, which combined with the long extra-thin profile, makes it excellent for keeping heat in the nozzle and out of the drive mechanism. It's also strong enough to allow that thin profile without any risk of breaking or bending during use.

My choice of pure titanium for the heater block and nozzle may seem a bit counter-intuitive. Pure titanium conducts heat slightly better than stainless steel, but still an order of magnitude worse than aluminum. So why use it for a heater block? That same thermal resistance makes it a stable system. Once it comes up to temperature, sudden changes in thermal conditions (heaters firing, fast extrusion) don't rapidly change the internal temperature. So while the cartridge heater powers away, the nozzle temperature remains constant.

Because the TiEnd is designed to get hotter than a normal hot-end, I decided the normal power-resistor heaters wouldn't cut it. To that end, I have sourced 12V 40W cartridge heaters. They get crazy hot crazy fast. And to match the heaters, I needed capable temperature sensing. The TiEnd will come with a K-type thermocouple for temperature measurement. This also means if your printer doesn't support thermocouples natively, you will need a thermocouple amplifier.

The TiEnd takes 1.75mm filament only.

The TiEnd is threaded with a standard M6x1 thread for mounting. This means it will be a drop-in replacement for a MakerBot MK7/8 extruder, or a QU-BD MBE. Because it's a standard thread, it's also very easy to make an adapter to any other extruder mounting style. It doesn't come with an adapter, but if you would like one, contact me.

About The TiEnd - Briefly*

The TiEnd is the culmination of months of thought, sketches, and a small amount of mathematics. It's the next step from my previous hot-end design, which has been running successfully in the field for months without a break. I took all the design elements I liked in existing hot-ends, and rolled them together into one design along with some twists of my own. It's made entirely of titanium (both pure and Ti6Al4V alloy) for strength and ultimate thermal stability. Titanium also has a mystical awesomeness about it. It's small and light to reduce extrusion head size and weight, which can help to speed up prints. And because it's made entirely of metal and heated by a powerful cartridge heater, it can get hot enough to melt all the hot new plastics - including polycarbonate - without melting or any other adverse effects.

About This Campaign

I have already completed the designs for the TiEnd. My goal is to raise funds for materials and specialized tooling to make a batch of four TiEnds. Although I am confident in my design, I know that I can't take it out of the prototype stage until it is proven. And that's where you come in. When you donate to this campaign, you don't just get a TiEnd of your very own (and the satisfaction of making it a reality). You are helping me make the TiEnd better by using it and pushing its limits. You can tell me what works and what doesn't, and I can make it better for future versions.

About Me

My name is Jeremy Bloyd-Peshkin. I've spent the last four years building and working on 3D printers. This is my second hot-end design, and my first attempt at crowdfunding a project. I have extensive experience in machining and fabrication, and the skill to bend bar stock to my will.

If funded, I will produce four TiEnds for donors. Any remaining funds will go towards future design revisions.

*The Nitty-Gritty

The TiEnd has some unusual features. It is the first hot-end to have no aluminum or brass in it. The thermal barrier is made of alloy Ti6Al4V titanium. This alloy has a ridiculously low thermal conductivity, which combined with the long extra-thin profile, makes it excellent for keeping heat in the nozzle and out of the drive mechanism. It's also strong enough to allow that thin profile without any risk of breaking or bending during use.

My choice of pure titanium for the heater block and nozzle may seem a bit counter-intuitive. Pure titanium conducts heat slightly better than stainless steel, but still an order of magnitude worse than aluminum. So why use it for a heater block? That same thermal resistance makes it a stable system. Once it comes up to temperature, sudden changes in thermal conditions (heaters firing, fast extrusion) don't rapidly change the internal temperature. So while the cartridge heater powers away, the nozzle temperature remains constant.

Because the TiEnd is designed to get hotter than a normal hot-end, I decided the normal power-resistor heaters wouldn't cut it. To that end, I have sourced 12V 40W cartridge heaters. They get crazy hot crazy fast. And to match the heaters, I needed capable temperature sensing. The TiEnd will come with a K-type thermocouple for temperature measurement. This also means if your printer doesn't support thermocouples natively, you will need a thermocouple amplifier.

The TiEnd takes 1.75mm filament only.

The TiEnd is threaded with a standard M6x1 thread for mounting. This means it will be a drop-in replacement for a MakerBot MK7/8 extruder, or a QU-BD MBE. Because it's a standard thread, it's also very easy to make an adapter to any other extruder mounting style. It doesn't come with an adapter, but if you would like one, contact me.

Organizer

Jeremy Bloyd-Peshkin

Organizer

Oak Park, IL